Welcome to HSE prosecutions in brief. A selection of the latest prosecutions by the HSE. Where possible, links are provided to relevant British Standards, guidance and publications.

|

| [relatedPosts title=”Related Posts”] |

|

|

Leading UK snack food manufacturer in court

Walkers Snack Foods Ltd has been fined after a 400 kilogramme block of compacted snack waste fell on a worker, breaking his leg.

The employee, who has asked not to be named, was working as a forklift truck driver at the company’s site in Newark Road, Lincoln, when the incident happened on 17 December 2010. He was trying to put the block into a wheeled bin when the bin overturned and the compacted waste landed on him, fracturing his lower left leg.

Lincoln Magistrates’ Court heard today (17 September) that waste pellets from the Quavers production line ran off a machine into a magnum bin – a large plastic box with slots underneath for the forks of a forklift truck. The pellets solidified into a large block, which could not be dug out of the magnum so the worker and a colleague used the forklift to turn the magnum over so the block fell out.

But as the block was then lifted into the wheeled bin, it became stuck at the top. When the two men attempted to move the bin, it tipped over causing the block of pellets to fall onto the employee.

He was off work for 15 weeks but has since returned to work with the company.

The Health and Safety Executive (HSE) told magistrates that the work had not been properly planned, supervised or carried out in a safe manner.

Walkers Snack Foods Ltd, of Theale, Reading, Berkshire, pleaded guilty to breaching Regulation 3(1) of the Management of Health and Safety at Work Regulations 1999 and Regulation 8(1) of the Lifting Operations and Lifting Equipment Regulations 1998. The company was fined a total of £20,000 and ordered to pay costs of £10,000.

Risk-Led Safety: Evidence-driven Management

Monmouth roof refurbishment company prosecuted after worker’s ladder fall

A Monmouth roof refurbishment company has been fined after an employee was injured in a six-metre fall from the roof of a house in Cirencester.

Cheltenham Magistrates’ Court heard today (17 September) that 26 year-old Lee Hanson, from South Shields, was using a roof ladder as he replaced tiles when the incident happened on 28 October 2011.

He lost his footing and fell six metres breaking his fall on a bush before he hit the ground. Mr Hanson broke his right wrist and suffered cuts and bruising. He was in hospital for two nights and was unable to return to work for six weeks.

An investigation by the Health and Safety Executive (HSE) found that Mr Hanson’s employer, Newlook Roof Coatings Ltd, failed to provide the protection necessary to safeguard workers at height.

The court heard that Newlook Roof Coatings had been served with a Prohibition Notice earlier in 2011 after a fitter was found working on a two-storey property in Newnham, Gloucestershire, without any edge protection. The notice prevented any further work anywhere in the country until sufficient safety measures had been put in place by the firm.

HSE had also given guidance and information on roof work, yet this had not been fully implemented.

Newlook Roof Coatings Ltd of Singleton Court, Wonastow Road, Monmouth, pleaded guilty to breaching sections 4(1)(a) and 4(1)(c) of the Work at Height Regulations 2005 and was fined a total of £10,000 and ordered to pay costs of £4,500.

British standard relating to working at heights.

Merseyside firm in court over life-threatening fall

A Merseyside firm has been sentenced after a worker received life-threatening injuries when he fell from scaffolding at a Croxteth sports centre.

The 43-year-old man from West Derby, who has asked not to be named, suffered a brain haemorrhage, fractured skull and collapsed lung in the incident at Croxteth Sports and Wellbeing Centre on 18 January 2011. His injuries also included a broken collar bone, ribs, wrist and fingers.

The worker was in intensive care for two weeks and his brain injury has had a long-term impact on his personality. He has also been unable to return to work as a result of his injuries.

His employer, CME Ceilings Ltd, was prosecuted by the Health and Safety Executive (HSE) after an investigation found the scaffolding tower the company provided for the job was unsafe.

Liverpool Magistrates’ Court was told today (18 September 2012) that the firm had been hired to install a suspended ceiling at the sports centre on Altcross Road in Croxteth but had made a last-minute change to its plan.

It had originally intended to use a scissor lift to reach the ceiling but did not arrange for the equipment to be delivered to the site, and so used a scaffolding tower instead.

The court heard the brakes on the wheels of the scaffolding tower had not been applied to stop it moving and there was no edge protection, including boards and rails, around the work platform to prevent employees falling off.

The man fell more than two metres to the concrete floor below when the tower started to move across the room as he was working.

The HSE investigation found the scaffolding tower had been made up of parts from several different manufacturers, all of which were in a poor or damaged condition.

CME Ceilings Ltd pleaded guilty to breaching the Health and Safety at Work etc Act 1974 by failing to ensure the safety of employees. The company, of Domville Road in Broad Green, was fined £5,000 and ordered to pay £5,000 in costs.

British standard relating to working at heights.

Safety failings led to farm worker’s injury

A Lincolnshire farmer and an agricultural machinery supplier have been fined after a young casual worker had three tendons in his right hand severed by a potato crusher.

The 25 year-old man, who does not wish to be named, had been working for farmer Timothy Dean, 55, at Waterloo Farm, Wilsford, Sleaford, to help with the potato harvesting, on 15 June 2009.

Grantham Magistrates’ Court was told that a potato crusher, designed and built by Grimme (UK) Ltd, had been fitted on the potato harvester but had no guard in place to protect workers against dangerous moving parts.

On the first day of using the crusher it kept getting blocked with stones. The team decided that each time a stone got stuck, they would signal the harvester driver, who would isolate the power on the machine, and the workers would reach into the crusher and knock the stones out using a lump hammer.

At one point when the crusher blocked, the young worker signalled the tractor driver, who stopped. However the driver had stopped for another reason and hadn’t isolated the power on the crusher. When the worker put his hand in it got caught up in the machinery severing the tendons.

The young worker has since regained some use of his hand.

In a prosecution brought by the Health and Safety Executive (HSE) magistrates heard that Grimme (UK) Ltd supplied the crusher attachment to farmer Timothy Francis Stuart Dean. There were defects found with the machine in that there was no safety guard to stop people accessing the dangerous moving parts and an instruction manual wasn’t provided.

HSE found that Timothy Dean had failed to properly assess the risks entailed in the work and hadn’t got a safe system of work for the farm workers.

Timothy Francis Stuart Dean of Thorpe Drive, South Rauceby, Sleaford, pleaded guilty to breaching Section 2(1) of the Health and Safety at Work etc Act 1974 and Regulation 3(1) of the Management of Health and Safety at Work Regulations 1999.

He was fined £20,000 and ordered to pay costs of £9,566.

Grimme (UK) Ltd, of Station Road, Swineshead, Boston, Lincolnshire, pleaded guilty to breaching Section 3(1) of the Health and Safety at Work etc Act 1974. They were fined £16,000 with costs of £15,000.

Since the incident Grimme (UK) Ltd has modified the crusher and provided an instruction manual.

British standards relating to machine safety.

Risk Management of Machinery and Work Equipment by John Glover

Company fined after worker suffers horrific head injuries

A West Midlands company has been fined after a worker suffered severe head injuries in a pneumatic metal press.

Wayne Hill, a maintenance engineer at H&E Knowles (Lye) Limited, was repairing the press when it unexpectedly started working and crushed his head. He was trapped for around ten minutes before colleagues were able to free him.

His nose and jaw were broken, his upper lip ripped off and he bit through his tongue. Mr Hill, 42, of Lye, Stourbridge, also sustained lacerations to the back of his head and neck, muscular damage to his left arm, severe neck pain and scratches and bruising to his left side.

He needed extensive reconstructive surgery and has been left with reduced sensitivity in his upper lip and nose, pain in his teeth and scarring to his shoulder. He underwent counselling after suffering nightmares and flashbacks.

Mr Hill was off work for nearly five months but has since returned to the company.

A Health and Safety Executive (HSE) investigation into the incident, which happened at the company’s Talbots Lane site in Brierley Hill, West Midlands on 18 August 2011, found the machine had a faulty interlocking guard.

Dudley and Halesowen magistrates heard the press, which takes a sheet of metal and forms it into a wheelbarrow body, should not have been able to operate if the door was open but the fault meant the machine did not detect this.

The court was also told that the machine was designed and built by the company 25 years ago. No technical drawings or any other documentation existed and an adequate risk assessment had never been carried out. The machine regularly broke down and maintenance staff were left to fix it with no instructions.

H&E Knowles (Lye) Ltd, of Waterfall Lane, Cradley Heath, pleaded guilty to breaching Section 2(1) of the Health and Safety at Work etc Act 1974 and was fined £18,000 with £7,220 costs.

British standards relating to machine safety.

|

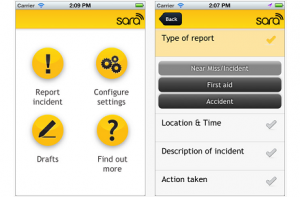

| Get this App on iTunes |

Severed finger leads to prosecution of food manufacturer

A Herefordshire food manufacturer has been fined after an employee severed her finger in an inadequately guarded machine.

Ewalina Giedziun, aged 29, from Hereford, sustained the injury while working on a suet packing line at Q Cold Limited’s Ledbury site on 17 October last year.

The tip of her index finger on her left hand was severed when she reached into the machine and came into contact with heated clamping jaws that crimp and seal plastic bags once filled. She was unable to work for several months as a result of the incident.

Hereford Magistrates’ Court heard today (20 September) that an investigation by the Health and Safety Executive (HSE) found that Q Cold Limited had assessed the risks associated with the packing line and had installed both fixed guards and interlocked doors to prevent access to dangerous moving parts. However, one of the fixed guards was not properly secured and was effectively useless.

Q Cold Limited, of Orchard Business Park, Bromyard Road, Ledbury, pleaded guilty to breaching Regulation 11(1) of the Provision and Use of Work Equipment Regulations 1998. The company was fined £2,000and ordered to pay £2,348 in costs.

British standards relating to machine safety.

Redhill company fined £167,000 over worker’s death

A Redhill-based construction company has been ordered to pay £210,000 in fines and costs after an employee died following an explosion on a construction site in central London. The explosion occurred following damage to an 11,000 volt live cable within an excavation.

Ioan Boboc, 22, a construction operative from north-west London, suffered burns over 60% of his body whilst he and other workers were using breakers and a shovel within the excavation at the corner of Charing Cross Road and Tottenham Court Road on 2 December 2008.

Southwark Crown Court heard (20 Sept) that Birse Metro Ltd had not informed workers that there were live cables in the excavation and that the company had failed to put adequate measures in place prevent them from coming into contact with the cable. Mr Boboc died of his injuries on Christmas Day 2008.

Birse Metro Ltd of Station Road, Redhill, Surrey, pleaded guilty to breaching Section 3(1) of the Health and Safety at Work etc Act 1974. The company was fined £167,000 and ordered to pay £43,000 in costs in the case brought by the Health and Safety Executive (HSE).

Risk-Led Safety: Evidence-driven Management

Tyneside firm fined after worker suffers toxic chemical burns

A Tyneside firm has been fined after a worker was soaked with a concentrated, corrosive chemical and suffered serious burns.

Michael Reid, 66, of North Shields, was employed as an electroplater at DMI (UK) Ltd when the incident happened on 30 January 2011.

In a prosecution brought by the Health and Safety Executive (HSE), North Tyneside Magistrates’ Court heard how as part of an electroplating process, the company used a stripping tank filled with a sodium hydroxide solution, which from time to time had to be topped up with a concentrate of the chemical.

Mr Reid was topping up the tank, by pumping the highly-caustic concentrated sodium hydroxide from a drum into the tank, when the hose attached to the pump came off, soaking him in the corrosive chemical.

He suffered serious burns to his legs and body, was in hospital for two weeks and had to undergo several skin grafts. Mr Reid had worked for the company since 1963 and retired in July 2011, having never returned to work following the incident.

The HSE investigation found that the hose had been attached to the pump with tape, rather than a permanent fixing such as a jubilee clip.

The company had failed to carry out a risk assessment of the procedure and did not carry out checks to ensure the hose was correctly attached. It had also failed to provide sufficient training for Mr Reid and other employees in the handling of sodium hydroxide and the protective equipment provided did not offer sufficient protection.

DMI (UK) Ltd, of Gloucester Road, West Chirton Industrial Estate, North Shields, was fined a total of £12,000 and ordered to pay £4,081 in costs after pleading guilty to breaching Section 2(1) of the Health and Safety at Work etc Act 1974 in that it failed to provide a safe system of work for topping up the stripping tank.

Salford firm sentenced over canal boat death

A Salford firm has been fined £50,000 over the death of a canal boat owner at a dry dock on the Bridgewater Canal.

Richard Ferris – a father of four and grandfather of nine – suffered critical injuries after he slipped on a plank and fell head first to the concrete floor below at The Boatyard in Worsley on 26 May 2010. He died in hospital later that day.

The owner of the site, Worsley Dry Docks Ltd, was prosecuted by the Health and Safety Executive (HSE) after an investigation found the wooden board leading to his boat had not been secured.

Manchester Crown Court heard today (21 September 2012) that the 61-year-old and his wife had taken their narrow boat to the dry dock to carry out maintenance work to the underneath while it was out of the water.

Mr Ferris was attempting to cross from his boat to the side of the dock and as he stepped onto the plank, known as a youngmans board, it began to move. He lost his balance and fell nearly two and a half metres to the floor of the dry dock.

The emergency services were called to the scene but he had suffered major head injuries and died as a result.

A HSE investigation found Worsley Dry Docks had failed to provide suitable access to users of the dry docks to allow them to move safely to and from their boats. The company has since ensured all of the planks at the dry dock have hand rails, and that they are properly secured before being used.

Worsley Dry Docks Ltd pleaded guilty to breaching Section 3(1) of the Health and Safety at Work etc Act 1974 after it failed to ensure Mr Ferris’s safety. The company was fined £50,000 and ordered to pay £15,185 in prosecution costs.